Feed Mill

Feed is the single most important factor that influences the growth rate and health of the birds. Whole white maize, soya cake, sunflower cake and feed additives are the main ingredients used to mix starter, growers’ and finishers’ feed. All the main ingredients for the feed mill are sourced locally, to produce the best quantity and quality feeds for that distinguished taste in our end product. No animal-based proteins, which tamper with the end taste of the birds, are included. 400 tonnes of maize are 150 tonnes of soya cake are consumed every month. With 20-tonne silos as part of the TFM, the chicken are guaranteed the best quantity and quality feed.

As part of the company’s commitment to continuously improve quality and efficiency, construction and installation of a 5-tonne per hour Buhler Pellet Mill that has greatly improved the Feed Conversion Ratios, was completed in June 2015.

As of 2017, the HMH-Rainbow feed mill produces a special blend of broiler and layer feeds sold under the Kuku Feeds trademark.

Broiler Farms

Agriculture Manager

Currently, the broiler farm consists of 5 farms with a total of 20 broiler houses and a total broiler farm capacity of 740,000 birds, each 8-week cycle. The farms are located 5-kms apart, a precaution against the spread of any disease from one farm to another.

The birds spend 35- 42 days in the broiler houses. Each house enjoys a mandatory 2-week resting period before new day-old chicks are brought in, when it cleaned, dusted, disinfected to prevent disease outbreak. High sanitation protocol is in place in the broiler farm and there is very minimal human contact with the birds, which reduces the incidence of disease and therefore the need for treatments. Each broiler house is fully enclosed and cannot be breeched by other animals or debris.

The houses are fully automated and environmentally controlled; feeding, watering, temperature, relative humidity, lighting, ammonia level and ventilation rate are all monitored and remotely controlled by a computer.

Key Benefits:

- More birds can be reared per square meter

- Lower mortality of birds

- Higher live weight

- Better Feed Conversion Ratio

- Lower input cost per bird

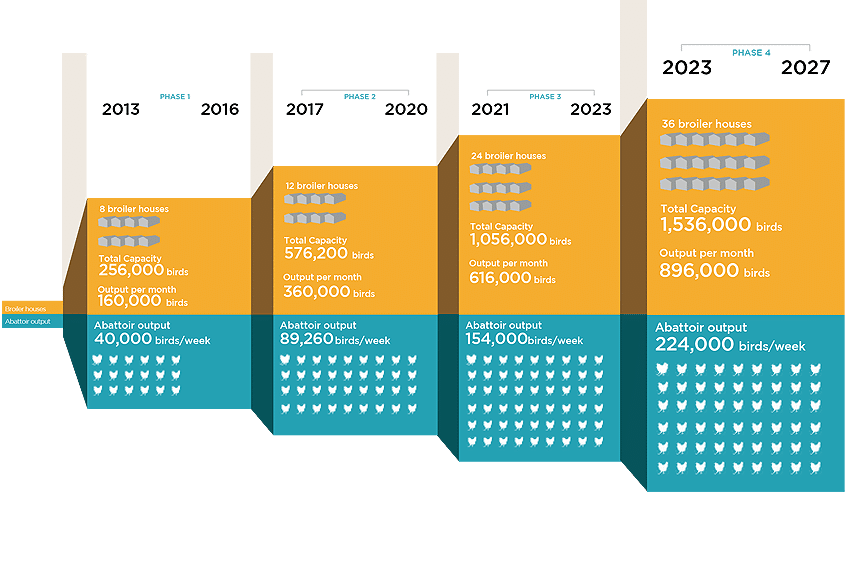

Production – Output Chart

Abattoir

The birds complete a full 6-week cycle in the broiler houses before they are ready for slaughter. The 15,000 Sqft processing facility is the first highly mechanised abattoir in Uganda and the largest chicken processing facility in East Africa. Because of high automation, human contact with the chicken is greatly minimised and all staff members that come in direct contact with slaughtered chicken are certified food handlers. During processing, no artificial ingredients or preservatives are injected into the birds.

Key Attributes:

- Highly automated which dramatically shortens the production time

- Temperature-controlled processes from the abattoir, through the distribution chain until the chicken reaches the customer

- Holding rooms that can accommodate 200 tonnes of chicken

- STAR certification including a traceability system that reduces the margin for error in the processes as well as Food Safety Systems Certification (FSSC22000), Halal and the Uganda National Bureau of Standards (UNBS), Qmark

Our Certifications

Distribution Centre

The Kampala based distribution centre located at the Head Office has a 500-tonne capacity holding room that is maintained at -20°C. The superior cold storage process, strengthened by our transportation department that covers both chilled and frozen distribution, ensures that the chicken that reaches our customer is always fresh and of the best quality.

The distribution centre in Kampala significantly shortens the delivery times to customers and additional quality checks are done before each dispatch to wholesale clients and retail shops